Custom Fitting Lighting Gels

09/10/15 12:37 Filed in: Lighting

So I’ve had a roll of lighting gels for years and for some odd reason, I’ve been a bit precious about them. I don’t have many and particularly the colour correction ones are absolutely necessary, so I have never cut them up! I keep them rolled up in a cardboard box, and every time I need to use them I have to take them out, spread them out on the floor, separate them, look for the ones that I need and then put the others back. What a hassle, and not always easy to spread them out. Then once I have the gel in hand it’s a case of C47’s clipping them to the front of the barn doors. Every now and then as the barn doors are altered the gel falls off, it makes the doors harder to operate and overall, a minor pain in the arse. Also, I only have three sheets of each colour correction gel meaning I can only correct three lights. If only there was another way. I don’t know why I didn’t think of this before, but simply cut the gels to fit the lights.

This is a familiar site.

A lamp with a gel clipped over the barn doors with a C47 or rather, a clothes peg, holding it on. Why is it, that most industries seem to have to invent their own language for things that already have names? Anyway, that’s a question for another time, back to the matter in hand!

It works, but it takes up a whole gel, or one that has been cut (if you aren’t as precious over gels as me), and can make it more difficult to move the barn doors, and it can fall off. There seems to be quite a bit of wasted gel in this method that is just getting scrunched up by the pegs. I was contemplating getting some additional CTB gels, to go with some new fresnel lamps that I have just got, and it suddenly dawned on me whilst looking at the new barn doors. Why not cut out a circle of gel and clip it to the inside of the barn doors? Not only would it mean that the gels go much further and I wouldn’t have to buy any new ones, but also, once clipped in, it wouldn’t get in the way of the operation of the barn doors, perfect!

The only problem though is cutting out the circle to the correct diameter. If only I had a template. Looking over to my shelf I saw a DVD spindle case which was 13.5cm in diameter, exactly the right size for the 300w/500w lamps I have!

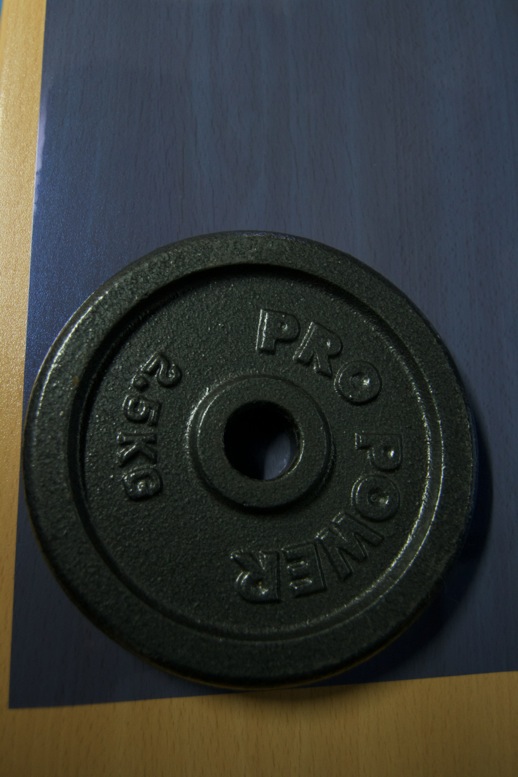

Problem is though, I also have a 650W lamp which is a different size. What are the chances of having another suitable template to hand?. Well on the floor was one of my dumbbell weights, 2.5kg, I was using for sandbag replacement (subject of another post), and spookily this was 16.5cm, exactly the right size for the 650W lamps!

I have the following gels that I really could do with for each lamp (i.e. colour correcting tungsten)

3 x 1/4 CTB

3 x 1/2 CTB

3 x Full CTB

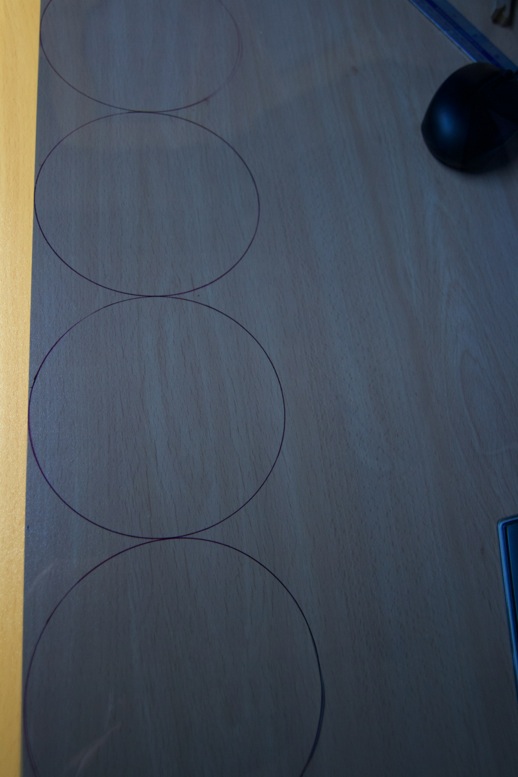

Even if I sacrificed an entire sheet, I still have spares for other lamps / unforeseen requirements. So the first thing was to mark off the cutouts using the templates.

Now I have 5 smaller gels, and two slightly larger ones for each CTB grade

Perfect! But, they need to be organised. This is how I used to find and use my gels. Boy, this was annoying, and invariably had to keep moving them on set, and they would get knocked etc etc, a real hassle.

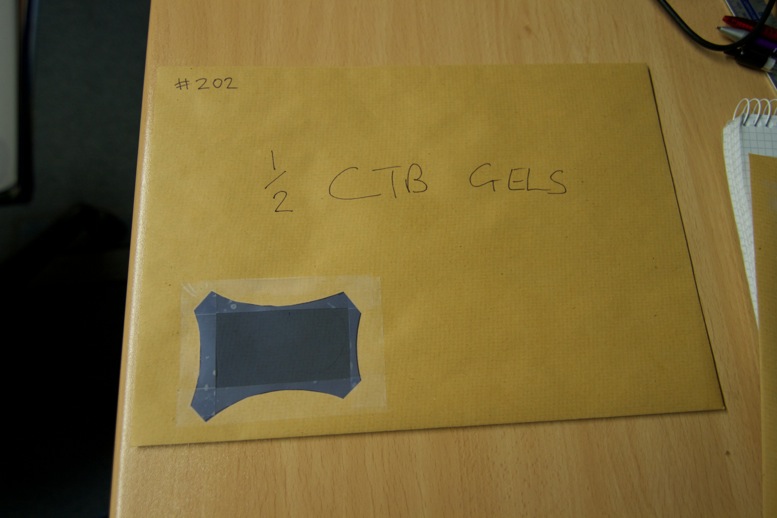

But now we have purpose cut-to-fit gels, the simple addition now of an A4 envelope and suitable labelling, including the Lee Filters reference top left, they can easily be taken to a shoot and found by anyone asked to get a specific gel. Another tip, and to make use of the little waste that was created, stick one of the gel offcuts to the front of the envelope. This way when someone goes to put a 1/2 CTB back they can quickly determine the correct envelope by matching it up.

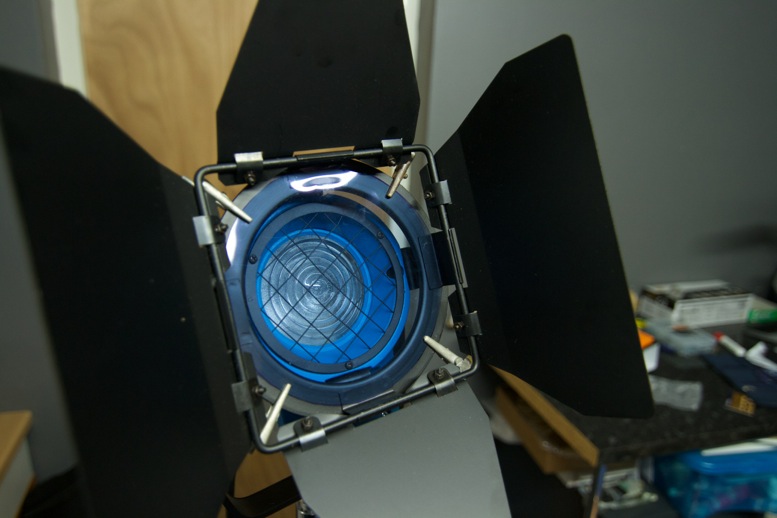

No more C47’s (not entirely true), instead just some small metal electrical crocodile clips and the gel is quickly applied to the lamp.

The results look way better and perform way better. You can move the lamp without knocking the gel off.

One thing that is is worth noting is that not all gels are made equal. This strategy I have employed moves the gel nearer the HOT lamp so the gels must be the high temperature type. I have tried this with the Lee filters I have and left it on for one hour with no ill effects at all. In fact, I was surprised that I could touch the crocodile clips, but again, that will depend on what lamp you have, the power etc, so always advisable to use heat resistant gloves. Now I said “no more C47’s”, well that’s not quite true. They are still needed for other things such as clamping on black wrap to stop light leakage coming out from the back.

So I am now very happy. I have gels for all my lights that do not interfere with the barn doors, yes if using black wrap that will still be clipped to them, but now only one thing is clipped on, and I still have loads of adhoc spare gels! Infact, I only used half of one sheet to make them for each CTB grade. I also have had only one sheet of diffusion gel (Lee #250) and some spun diffuser material, so now I can cut that gel up and have soft diffuse light for all my lamps!

Like I said at the start, I can’t believe I haven’t done this years ago!

blog comments powered by Disqus